Fill a Valid Welder Performance Qualification Record Template

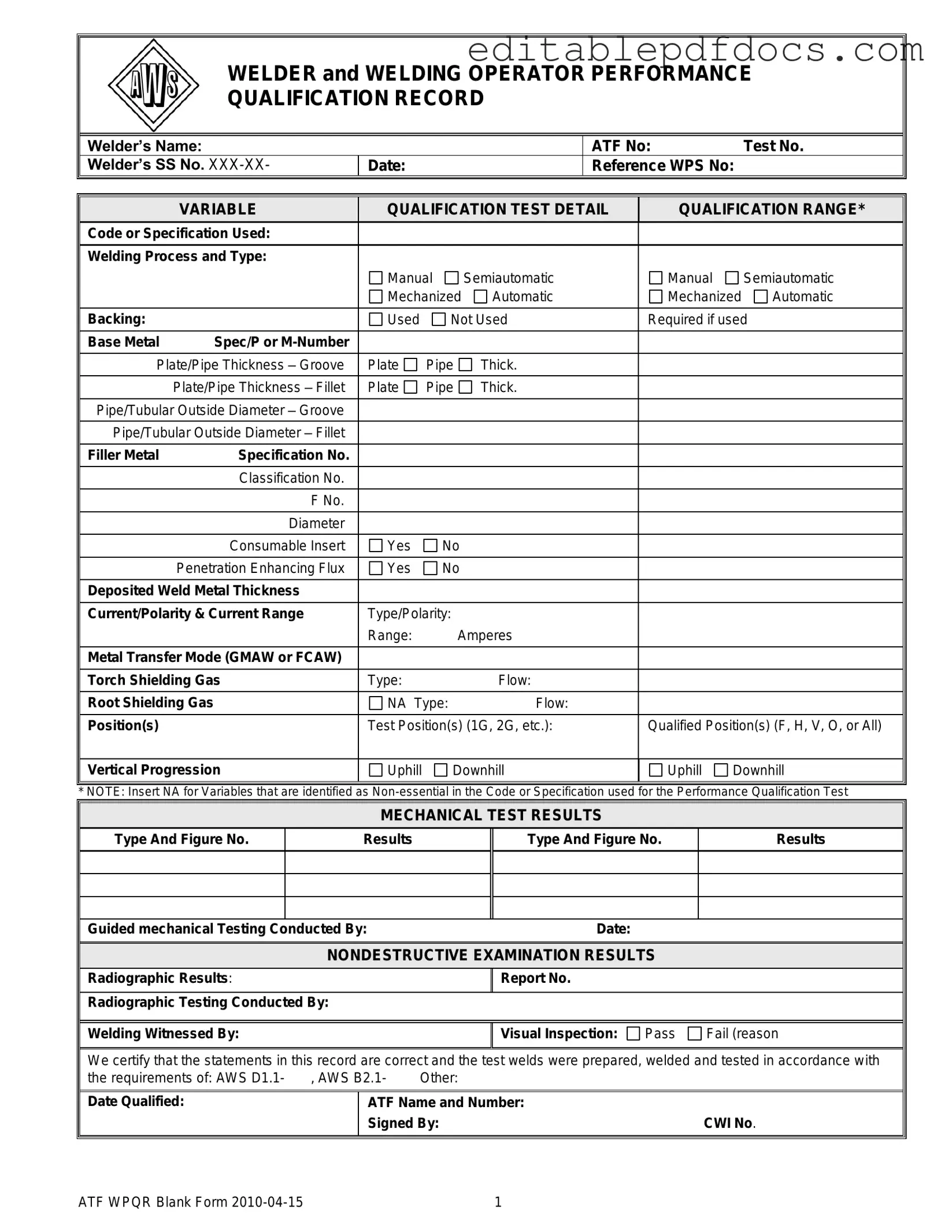

The Welder Performance Qualification Record form is an essential document in the welding industry, serving as a comprehensive record of a welder's qualifications and capabilities. This form captures crucial information such as the welder's name, identification numbers, and the specific tests they have completed. It outlines the reference Welding Procedure Specification (WPS) and details the various welding processes employed, whether manual, semiautomatic, or automatic. The form also includes important variables like base metal specifications, thicknesses, and filler metal classifications. Furthermore, it documents the results of mechanical tests and non-destructive examinations, ensuring that the welder meets industry standards. By providing a clear picture of a welder's skills and qualifications, this record plays a vital role in maintaining quality and safety in welding operations.

Document Details

| Fact Name | Description |

|---|---|

| Purpose | The Welder Performance Qualification Record form verifies a welder's ability to produce sound welds according to specific codes and standards. |

| Essential Information | The form requires details such as the welder's name, social security number, and test number, ensuring accurate identification. |

| Welding Processes | It includes various welding processes such as manual, semiautomatic, mechanized, and automatic, allowing flexibility in qualifications. |

| Qualification Range | The record outlines the qualification range, which includes variables like base metal specifications and thicknesses. |

| Mechanical Testing | Results from mechanical tests are documented, confirming the integrity of the welds produced by the welder. |

| Non-Destructive Examination | Non-destructive examination results, such as radiographic testing, are included to ensure quality control and compliance. |

| Governing Laws | In many states, compliance with AWS D1.1 and AWS B2.1 is necessary for the qualification process, ensuring adherence to national standards. |

Dos and Don'ts

When filling out the Welder Performance Qualification Record form, attention to detail is crucial. Here are five important do's and don'ts to keep in mind:

- Do ensure that all personal information, such as the welder’s name and Social Security number, is accurate and clearly written.

- Do reference the correct Welding Procedure Specification (WPS) number to avoid any discrepancies.

- Do include all relevant details about the welding process, including the type of metal and the thickness of the materials.

- Do verify that the mechanical test results and non-destructive examination results are documented properly.

- Do sign and date the form to validate the qualifications and the accuracy of the information provided.

- Don't leave any sections of the form blank; incomplete information can lead to delays in processing.

- Don't use abbreviations or shorthand that may not be universally understood.

- Don't forget to check for any non-essential variables that should be marked as NA.

- Don't overlook the importance of having the form reviewed by a certified welding inspector before submission.

- Don't submit the form without ensuring that all test welds were conducted according to the specified standards.

Documents used along the form

The Welder Performance Qualification Record form is an essential document that verifies a welder's skills and qualifications. However, it is often used in conjunction with several other forms and documents that help ensure compliance with industry standards and regulations. Below is a list of related documents that are commonly associated with the Welder Performance Qualification Record.

- Welding Procedure Specification (WPS): This document outlines the specific procedures and parameters that must be followed during the welding process. It serves as a guideline for welders to ensure consistency and quality in their work.

- Procedure Qualification Record (PQR): The PQR demonstrates that a specific welding procedure can produce welds that meet the required standards. It includes details about the materials, welding process, and test results from the procedure.

- Material Test Reports (MTR): MTRs provide documentation of the physical and chemical properties of the materials used in welding. These reports ensure that the materials meet the necessary specifications for the project.

- Welder Certification Card: This card verifies that a welder has successfully completed the necessary training and testing to be certified in specific welding processes. It is often required for employment in the welding industry.

- Non-Destructive Testing (NDT) Reports: NDT reports document the results of inspections that do not damage the welds. These inspections can include methods like radiography, ultrasonic testing, and magnetic particle testing to ensure weld integrity.

- Inspection and Test Plans (ITP): An ITP outlines the specific inspections and tests that will be conducted throughout the welding process. It helps ensure that all quality assurance measures are followed.

- Bill of Sale Form: This document is essential for the transfer of ownership of personal property, providing crucial information about the buyer, seller, and the item sold. For convenience, you can find a Fillable Forms that simplify the process.

- Quality Control Plan (QCP): This plan details the quality control measures that will be implemented during the welding process. It ensures that all aspects of the work meet the required standards.

- Daily Welding Reports: These reports provide a daily account of the welding activities performed, including the number of welds completed, materials used, and any issues encountered during the day.

- Welder Training Records: These records document the training and continuing education that welders have completed. They are important for demonstrating ongoing compliance with industry standards.

Each of these documents plays a critical role in ensuring that welding operations meet safety and quality standards. Together, they create a comprehensive framework that supports the integrity of the welding process and the qualifications of the welders involved.

Popular PDF Forms

Credit Application Form - Specify your business’s annual revenue to determine financial health.

In New York, employing a Hold Harmless Agreement form is crucial for both individuals and businesses, as it safeguards against liabilities arising from the actions of another party. This agreement not only clarifies the responsibilities and rights of everyone involved but also fosters a sense of security in various transactions. For those interested in drafting a Hold Harmless Agreement, a great resource can be found at https://nyforms.com/hold-harmless-agreement-template, which provides an accessible template to ensure all necessary legal protections are in place.

Lease Agreement Trucking - Responsibilities for cargo safety and operational procedures are clarified within the agreement.

Similar forms

Welding Procedure Specification (WPS): This document outlines the specific parameters and procedures for a welding operation. Like the Welder Performance Qualification Record, the WPS details the welding processes, materials, and techniques used. Both documents ensure that the welding is performed consistently and according to established standards.

Procedure Qualification Record (PQR): The PQR verifies that a specific welding procedure can produce welds that meet certain requirements. Similar to the Welder Performance Qualification Record, it documents the results of tests performed on welds made using the specified procedure, ensuring that the process is reliable and effective.

- Commercial Lease Agreement: This form establishes the terms under which a commercial property is rented, detailing essential aspects such as rental amount and lease duration; businesses can download the document to ensure compliance and clarity in their leasing arrangements.

Welder Certification: This document certifies that a welder has the necessary skills and qualifications to perform welding tasks. It is akin to the Welder Performance Qualification Record in that both confirm a welder's capabilities and adherence to industry standards, providing assurance of quality and safety.

Non-Destructive Testing (NDT) Report: An NDT report evaluates the integrity of welds without causing damage. Like the Welder Performance Qualification Record, it is crucial for ensuring that the welds meet quality standards. Both documents contribute to the overall assessment of welding quality and safety.

Common mistakes

Filling out the Welder Performance Qualification Record form accurately is crucial for ensuring compliance and validation of welding skills. However, several common mistakes can lead to issues down the line. One frequent error is omitting the welder's name or incorrect entry of the ATF number. This information is essential for identifying the welder and linking their qualifications to the specific test.

Another common mistake involves the incorrect selection of the welding process and type. The form requires precise categorization as manual, semiautomatic, mechanized, or automatic. Misclassifying the welding process can invalidate the qualification and cause significant delays in certification.

People often neglect to provide complete details about the base metal specifications. Failing to include the P or M number can lead to confusion regarding the materials used, which is critical for evaluating the weld's integrity. Additionally, not indicating the thickness of the plate or pipe can result in misinterpretation of the qualification range.

Inaccuracies in the filler metal specification can also be problematic. It is essential to include the correct classification number and diameter of the filler metal. Missing or incorrect data in this section may affect the performance evaluation and subsequent approvals.

Individuals frequently overlook the importance of documenting the mechanical test results. This section should reflect accurate results from guided mechanical testing. Incomplete or missing test results can undermine the credibility of the qualification record.

Not specifying the position(s) tested and qualified is another mistake that can have serious implications. The form must clearly indicate the test and qualified positions, such as 1G, 2G, or others. Inconsistencies here can lead to questions about the welder's capabilities in different orientations.

Many people fail to include the non-destructive examination results. This section is vital for confirming the quality of the welds. Omitting this information can raise red flags during audits or reviews, potentially jeopardizing the welder's qualification.

Finally, signatures and dates are often missing or incorrectly filled out. The certification of the record requires the appropriate signatures, including the Certified Welding Inspector (CWI). A lack of proper documentation can result in the qualification being deemed invalid.